Own developments for the packaging industry.

"success by Innovation"

Due to the company's many years of exprerience in the envelope and packaging industry, a number of newly developed products have been designed and manufactured to meet a wide range of customer requirements.

This is an individually implementable apllication system consisting of different aggregates:

a WTB - Angle Conveyor Belt,

a SPA - Silicone Paper Applicator

and a TSA - Tear Strip Applicator.

These machines are used in particular for processing environmentally friendly cardboard and paper packaging.

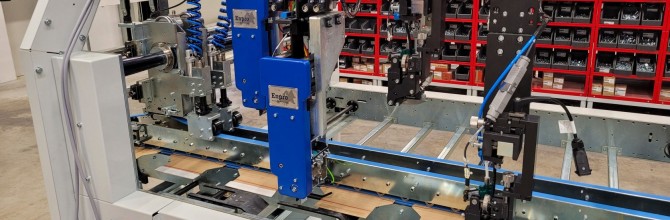

WTB - ANgle Conveyor belt

The WTB (German: Winkeltransportband) is designed for conveying, diverting and processing packaging materials with high production speeds and various format sizes.

At the heart of the machine - the transport track - usually tear tape threads, hot melt and one or more release paper strips are applied to the packaging blanks which are deflected by 90°.

Product Details

Thanks to its mobility, the angle conveyor belt system can be flexibly integrated into existing production lines and can accommodate additional units.

Manifold functions and possibilities:

- Transport of packaging blanks at high school

- 90° deflection

- Separation of blanks from the shingle stream

- Integration of glue application units

- Integration of MAS aggregates for the application of release paper strips

- Integration of TSA aggregates for the application of tear-off threads

- Return of balnks to the shingle stream in the usual direction

If necessary, transport straight ahead via bypass function - if redirection and processing are temporarily not desired.

If you are interested or if you have questions or suggestions, please do not hesitate to contact us. We will be happy to help you.

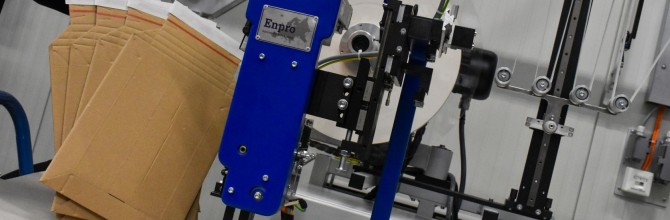

MAS - Multiapplicationsystem

A MAS is used for applying non-adhesive material strips of paper or plastic to a glue line. By using the

MAS you can realize both so-called self-adhesive closures (glue line covered with release / silicone

paper strips) and tear-off thread (glue line covered with paper or plastic strips).

Productdetails:

- Speed: up to 300m/min

- Tolerances: Length ± 0,25mm, position ± 2mm

- Strip width: 6mm-150mm

- Strip length: from 110mm (from 60mm is possible with special devices and appropriate parameter settings)

- Type of winding: disk rolls and cross winding spools

- Core diameter: 76mm (disk rolls) 152mm (cross winding spools)

- Core wide: 15-50mm (disk rolls) 180/250/300mm (cross winding spools)

- material width: 15-50mm (disk rolls) 15-30mm (cross winding rolls)

It is possible to apply up to 5 strips in a row on a blank.

If you are interested, or if you have questions or suggestions, please do not hesitate to contact us.. Special requirements are also possible. We are looking forward to help you.

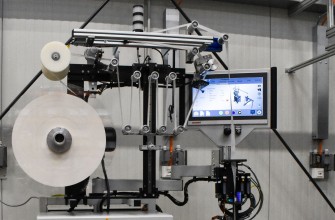

TSA-

Tear strip applicator

A Tear Strip Applicator consists of a dispenser and an application head for the tear strip. Our machine is also known as a tear tape applicator, tear strip dispenser, tear tape dispenser and processes tear tape. The TSA dispenser holds the tear tape roll in place and feeds the tape tension-free to the application head. The TSA-application head ensures trouble-free application of the tape to the carrier material (cardboard packaging, etc.).

Productdetails:

- Spped: up to 170m/min

- Tolerances: Length ± 2mm, Position ± 3mm

- Strip width: 4mm-6mm (other widths available on request)

- Strip length: 60mm - endless

- Type of winding: cross winding spools

- Core diameter: 152mm

- Core wide: 180mm

If you are interested, or if you have questions or suggestions, please do not hesitate to cantact us. Special requierments are also possible. We are looking forward to help you.